Published TCIMAIL newest issue No.199

Maximum quantity allowed is 999

Please select the quantity

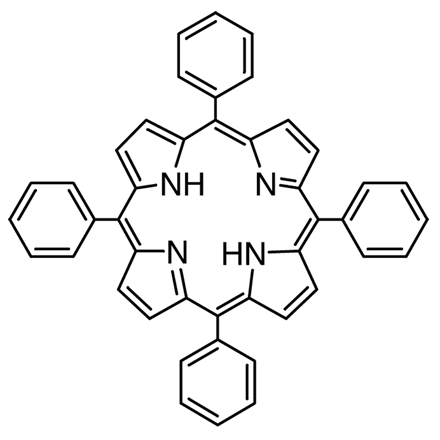

CAS RN: 917-23-7 | Product Number: T1359

Tetraphenylporphyrin (Chlorin free)

Purity: >98.0%(HPLC)

Synonyms:

- Tetraphenylporphine (Chlorin free)

- TPP (Chlorin free)

Product Documents:

| Size | Unit Price | Belgium | Japan* | Quantity |

|---|---|---|---|---|

| 1G |

€132.00

|

7 | ≥100 |

|

*Stock available in Belgium will be delivered in 1 to 3 days

*Stock available in Japan will be delivered in 1 to 2 weeks (excludes regulated items and dry ice shipments).

| Product Number | T1359 |

Purity / Analysis Method

|

>98.0%(HPLC) |

| Molecular Formula / Molecular Weight | C__4__4H__3__0N__4 = 614.75 |

| Physical State (20 deg.C) | Solid |

Storage Temperature

|

Room Temperature (Recommended in a cool and dark place, <15°C) |

| Store Under Inert Gas | Store under inert gas |

| Condition to Avoid | Air Sensitive |

Packaging and Container

|

1G-Glass Bottle with Plastic Insert (View image) |

| CAS RN | 917-23-7 |

| Reaxys Registry Number | 379542 |

| PubChem Substance ID | 87577126 |

| MDL Number | MFCD00011680 |

Specifications

| Appearance | Orange to Brown to Dark purple powder to crystal |

| Purity(HPLC) | min. 98.0 area% |

| Tetraphenylchlorin | max. 0.5 % |

| NMR | confirm to structure |

Properties (reference)

GHS

Related Laws:

| EC Number | 213-025-9 |

Transport Information:

| HS Number | 2933998090 |

Application

Molecular-weight Controlled Polymerization Using Aluminum-porphyrins

Typical Procedure:

The flask containing tetraphenylporphine ((TPP)H2)(1.0 mmol) is purged with dry N2, and then CH2Cl2 (20 mL) is introduced to dissolve (TPP)H2. To this solution is added Et2AlCl (1.2 mmol, 20% excess to (TPP)H2) by syringe under a N2 atmosphere at room temperature with stirring. After a definite time, the volatile materials are removed from this reaction mixture under reduced pressure to give a purple solid (TPP)AlCl) with metallic luster. CH2Cl2 (20 mL) is introduced to this flask to dissolve the product, to obtain the catalyst solution.

To the catalyst solution ((TPP)AlCl 20.4 mM) with stirring is added β-propiolactone (6.12 mol) by syringe at room temperature in a N2 atmosphere. After a definite time, a large excess of methanol is added to the reaction mixture to stop the polymerization, and then volatile materials are removed under reduced pressure to leave the product. The polymer is isolated as a slightly yellow-green powder by precipitation of the product from chloroform/methanol after shaking the chloroform solution with dilute hydrochloric acid.

The gel permeation chromatogram (GPC) of the resulting polymer shows the weight average molecular weight to the number average molecular weight (Mw/Mn) : 1.26 and the number average molecular weight (Mn) : 3500.

The flask containing tetraphenylporphine ((TPP)H2)(1.0 mmol) is purged with dry N2, and then CH2Cl2 (20 mL) is introduced to dissolve (TPP)H2. To this solution is added Et2AlCl (1.2 mmol, 20% excess to (TPP)H2) by syringe under a N2 atmosphere at room temperature with stirring. After a definite time, the volatile materials are removed from this reaction mixture under reduced pressure to give a purple solid (TPP)AlCl) with metallic luster. CH2Cl2 (20 mL) is introduced to this flask to dissolve the product, to obtain the catalyst solution.

To the catalyst solution ((TPP)AlCl 20.4 mM) with stirring is added β-propiolactone (6.12 mol) by syringe at room temperature in a N2 atmosphere. After a definite time, a large excess of methanol is added to the reaction mixture to stop the polymerization, and then volatile materials are removed under reduced pressure to leave the product. The polymer is isolated as a slightly yellow-green powder by precipitation of the product from chloroform/methanol after shaking the chloroform solution with dilute hydrochloric acid.

The gel permeation chromatogram (GPC) of the resulting polymer shows the weight average molecular weight to the number average molecular weight (Mw/Mn) : 1.26 and the number average molecular weight (Mn) : 3500.

References

- T. Aida, R. Mizuta, Y. Yoshida, S. Inoue, Makromol. Chem. 1981, 182, 1073.

- T. Yasuda, T. Aida, S. Inoue, Macromolecules 1984, 17, 2217.

- S. Asano, T. Aida, S. Inoue, J. Chem. Soc. Chem. Commun. 1985, 1148.

- Y. Watanabe, T. Yasuda, T. Aida, S. Inoue, Macromolecules 1992, 25, 1396.

- M. Komatsu, T Aida, S. Inoue, J. Am. Chem. Soc. 1991, 113, 8492.

- H. Sugimoto, M. Kuroki, T.Watanabe, C. Kawamura, T. Aida, S. Inoue, Macromolecules 1993, 26, 3403.

PubMed Literature

Documents

Product Articles

[Product Highlights] Molecular-weight Controlled Polymerization Using Aluminum-porphyrinsProduct Documents (Note: Some products will not have analytical charts available.)

Safety Data Sheet (SDS)

Please select Language.

The requested SDS is not available.

Please Contact Us for more information.

Specifications

C of A & Other Certificates

Please enter Lot Number

Incorrect Lot Number. Please input only the 4-5 alphanumeric characters before the hyphen.

Sample C of A

This is a sample C of A and may not represent a recently manufactured lot of the product.

A sample C of A for this product is not available at this time.

Analytical Charts

Please enter Lot Number

Incorrect Lot Number. Please input only the 4-5 alphanumeric characters before the hyphen.

The requested analytical chart is not available. Sorry for the inconvenience.

![TPP (=Tetraphenylporphyrin) [Ultra-high sensitive spectrophotometric reagent for Cu] TPP (=Tetraphenylporphyrin) [Ultra-high sensitive spectrophotometric reagent for Cu]](/medias/A5012.jpg?context=bWFzdGVyfHJvb3R8NDUyNTN8aW1hZ2UvanBlZ3xhREJtTDJoaU1DODRPVEk0TlRFeU1UZ3dNalUwTDBFMU1ERXlMbXB3Wnd8MmU4MjU4OThkYTY4ODU5YzFjZmE4YTBjMjQ3NjkwM2UxYTNmNTllN2RkMzMyZDFkODJjOGY3ZTQwZmFhNjk1OA)